IN-HOUSE Prefabrication

An Innovative Approach to Project Planning and Delivery

Our fully staffed PreFabrication Shop further enhances Aldridge’s commitment to improving safety on the job site. By minimizing construction site elements to a clean and temperature-controlled workshop, Aldridge ensures a higher-quality product while simultaneously reducing safety hazards. What was once being built on the side of the road, is now being delivered pre-packaged, pre-assembled, and ready to install on-site. With over 1,000 PreFab orders completed each year and three dedicated warehouse spaces, the team is capable of highly advanced and large-scale modular construction.

Our PreFabrication Shop relies heavily on the successful implementation of the Aldridge Project Planning process and further enhances Aldridge’s commitment to improving project cost, quality, and time.

Cost - Our pre-planning phase allows us to identify project elements to build prior to site arrival, reducing our overall costs.

Quality - Minimizing construction site elements to a clean and temperature-controlled workshop ensures a higher-quality product while simultaneously reducing safety hazards.

Time - By identifying project elements to create prior to field delivery, we are able to decrease build time and improve project efficiency - even when working around other subcontractors and their deadlines.

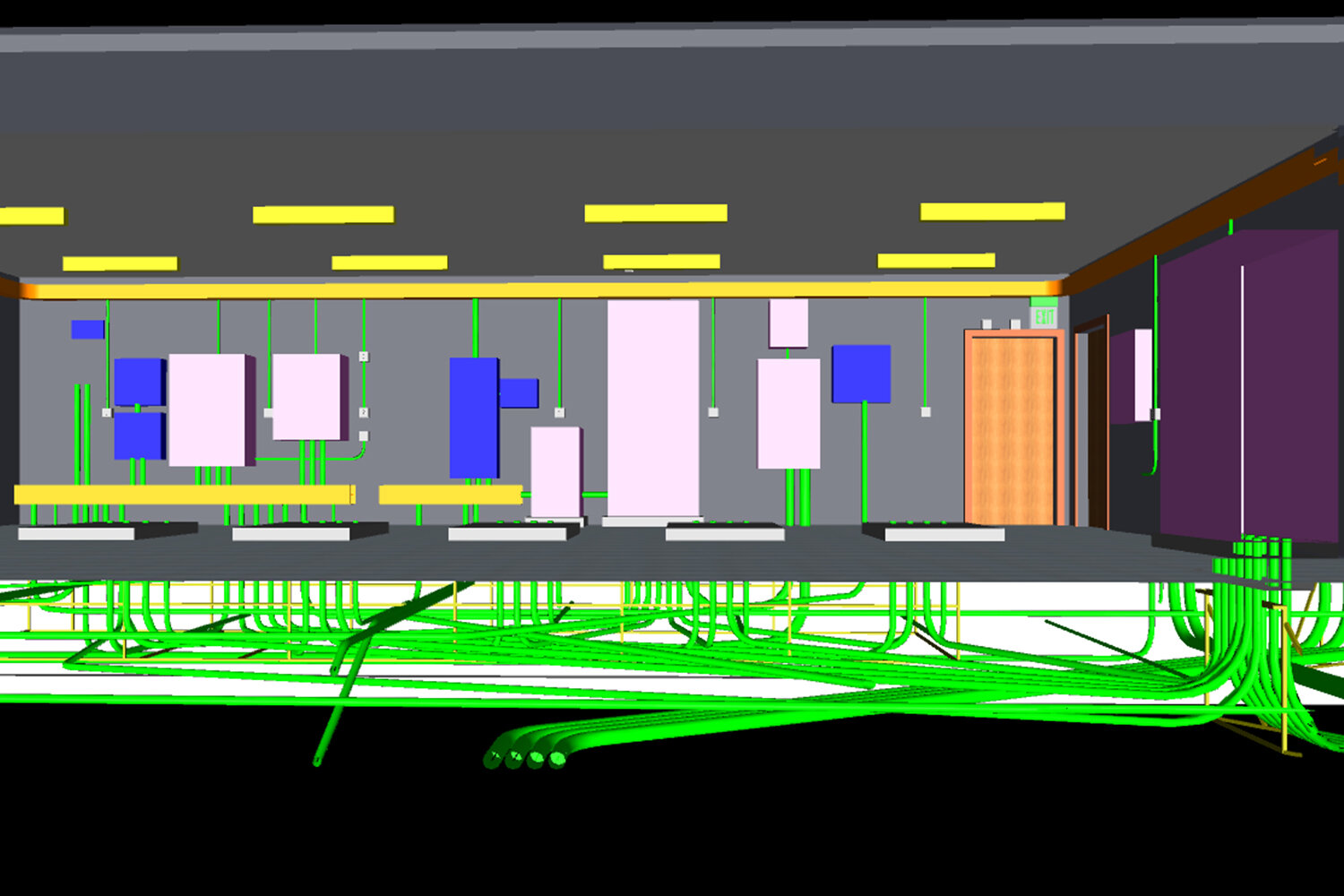

Aldridge’s BIM operators work collaboratively with the PreFab team to carefully plan how best to utilize Prefabrication on each project. Our staff of four full-time CAD/BIM Operators can support all 2D, 3D, BIM, scanning, and trimble needs.